رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

2023.10.8 The working principle of the jaw crusher is to use compression force to compress coal between a fixed jaw and a movable jaw for coarse crushing. The jaws are lined with hard materials such as manganese steel to

Read More

2024.5.20 We have a coal hammer mill. It reduces coal size from 50 mm to 1 mm. We have been observing air on the top of the hammer mill and it feels like hammer mill is

Read More

2015.7.1 This article, which describes the historical influences and state-of-the-art design for the various coal preparation unit operations, is organized to distinguish between

Read More

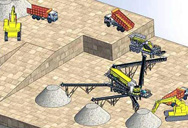

2016.3.11 Crusher Plant Layout. Most crushing plants are now designed on the lines shown in Fig. 1, which is a diagrammatic view of a two-stage arrangement.

Read More

Unit operations of coal preparation can broadly be divided into coal cleaning and three associated processes: (a) the pretreatment of feed coal, (b) subsequent treatment of products;

Read More

A coal preparation plant (CPP; known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock,

Read More

Crushing and breaking. Run-of-mine coal must be crushed to an acceptable top size for treatment in the preparation plant. Typical crushing and breaking devices are feeder breakers, rotary breakers, hammer mills, and roll crushers. Sizing.

Read More

Crushing Technology. There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition. Most crushers employ a combination of all these

Read More

2012.2.20 Coal jaw crusher is utilized widely as a efficient coal crusher and applied in coal processing provider. Some coal can be a mixture of coal and waste rock symbiotic parting

Read More

2020.4.20 Crushing is the process of reducing the size of materials so that they can be ... of reducing the size of materials so that they can be further processed. In addition to being used in the chemical, coal industry, ... a

Read More

2021.5.28 way, the models of coal flotation kinetics, with particular emphasis on the impact of particle size on coal kinetic rate, recovery, and product quality. The efficiency of the coal feed beneficiation process depends on a number of factors [16,17]. Density composition of the feed and the share of waste fractions in it are the most important of them.

Read More

2023.10.25 This research delineates the energy dissipation characteristics in coal crushing under impact loads, leveraging the capabilities of Separated Hopkinson Pressure Bar experimental system. A ...

Read More

2024.7.15 MB Crusher, a global leader in crushing and screening solutions, is proud to introduce the groundbreaking HDS line for coal crushing to the Indian market. Designed to meet the unique challenges faced by the coal industry, the HDS line promises to significantly enhance efficiency, mobility, and cost-effectiveness for coal crushing operations across India.

Read More

Crushing Operations Screener Operation Purpose: The purpose is to provide guidance to Timbro Contracting employees on how to complete specific tasks safely. Safe work procedures must clearly identify the steps required to complete the task, the hazards and the control measures. Scope:

Read More

2018.12.3 Research into the on-line analysis of coal began in the mid-1970s as a result of the increase in the price of coal resulting from the ‘oil shock’ of the early 1970s and the rapid growth in the Australian coal industry. This research led to the development of a range of on-line coal analysis systems.

Read More

DSMAC has many years manufacturing experience in coal crushing line (coal crushing, washing plant and belt conveyor). DSMAC is a major coal crushing equipments supplier for power plants, coke ovens, and crushing a wide range of raw and manufactured materials for industry. For DSMAC, the clients' needs have always been our primary concern.

Read More

Coal is transported from Pit B to Run of Mine (ROM) stock or directly to Coal Crushing Plant (CCP). The capacity of our MIFA Coal Crushing Plant is 2500 tons per hour with 3 units of Fix Plant and 1 unit of Mobile Plant Crusher with Coal Sizing crushed from 400 mm to 100 mm (lumpy) and 50 mm (fines), The majority of ROM coal is low ash insitu, clean, and directly

Read More

Energy Evolution and Coal Crushing Mechanisms Involved in Coal and Gas Outburst Chaolin Zhang,1,2 Peizhong Wang,1 Xianfeng Liu,3,4 Enyuan Wang,1,2 Qiaozhen Jiang,1 and Mingliang Liu1 ... straight line with dust collection bags attached at the ends to collect the coal dust thrown out of the roadway (Zhang et al., 2022b).

Read More

MB Crusher, a global leader in crushing and screening solutions, is proud to introduce the groundbreaking HDS line for coal crushing to the Indian market. Designed to meet the unique challenges faced by the coal industry, the HDS line promises to significantly enhance efficiency, mobility, and cost-effectiveness for coal crushing operations across India.

Read More

Coal Crushing Production Line in Pakistan Last Updated :May 06nd,2019. Published 2019. 22/Mar. 09:02. HX china. share. Case Material Max Feeding size: 125-1200mm Output size: 10-350mm Email us info@hxjq contact.

Read More

1.2 Reduction and division procedures are prescribed for coals of the following groups: 1.2.1 Group A includes coals that have been cleaned in all sizes. 1.2.2 Group B includes all other coals. Unknown coals are to be considered under Group B. 1.2.3 Group A allows smaller weight laboratory samples to be retained than Group B.

Read More

With more underground mine operators under pressure to extract more coal and industrial minerals with fewer resources, ... From hard material to clays and sticky materials, our crushing equipment line-up provides flexible, productive and

Read More

Produces a dust-encapsulating foam that is ideal for a variety of applications including foam cleaning, coal transfer houses, coal crushing, coal storage, and other areas where coal dust is created. The low-moisture foam properties reduce BTU loss and reduce the risk of shorting out electrical components during on-line facility cleaning applications.

Read More

The reclaimed coal can be delivered to any of three destinations; the Collie ‘A’ power station conveyor, the Muja power station conveyor or the train and truck loadout bin. A 1200–tonne train can be loaded in one hour. Coal product quality is carefully monitored as it is being stacked. An on-line ash analyser continuously monitors ash ...

Read More

Coal crushing plant is the production line of a large-scale open-pit mining era. It integrates raw materials feeding, crushing, conveying, screening, dust removal, and quick-installing systems into one unit.

Read More

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. Besides, it is mainly used to crush coal cinder, slag, shale, coal gangue, and other materials.

Read More

2024.8.19 MB Crusher, a global leader in crushing and screening solutions, is proud to introduce the groundbreaking HDS line for coal crushing to the Indian market. Designed to meet the unique challenges faced by the coal industry, the HDS line promises to significantly enhance efficiency, mobility, and cost-effectiveness for coal crushing operations across India.

Read More

Energy,

Read More

Complete product series, through coarse crushing, medium crushing, fine crushing and ultra-fine crushing operations. AIMIX has jaw crusher, impact crusher, cone crusher and sand making machine as the core crushing equipment,with a full range of models to meet the customer’s tonnage and construction aggregate production needs.

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.